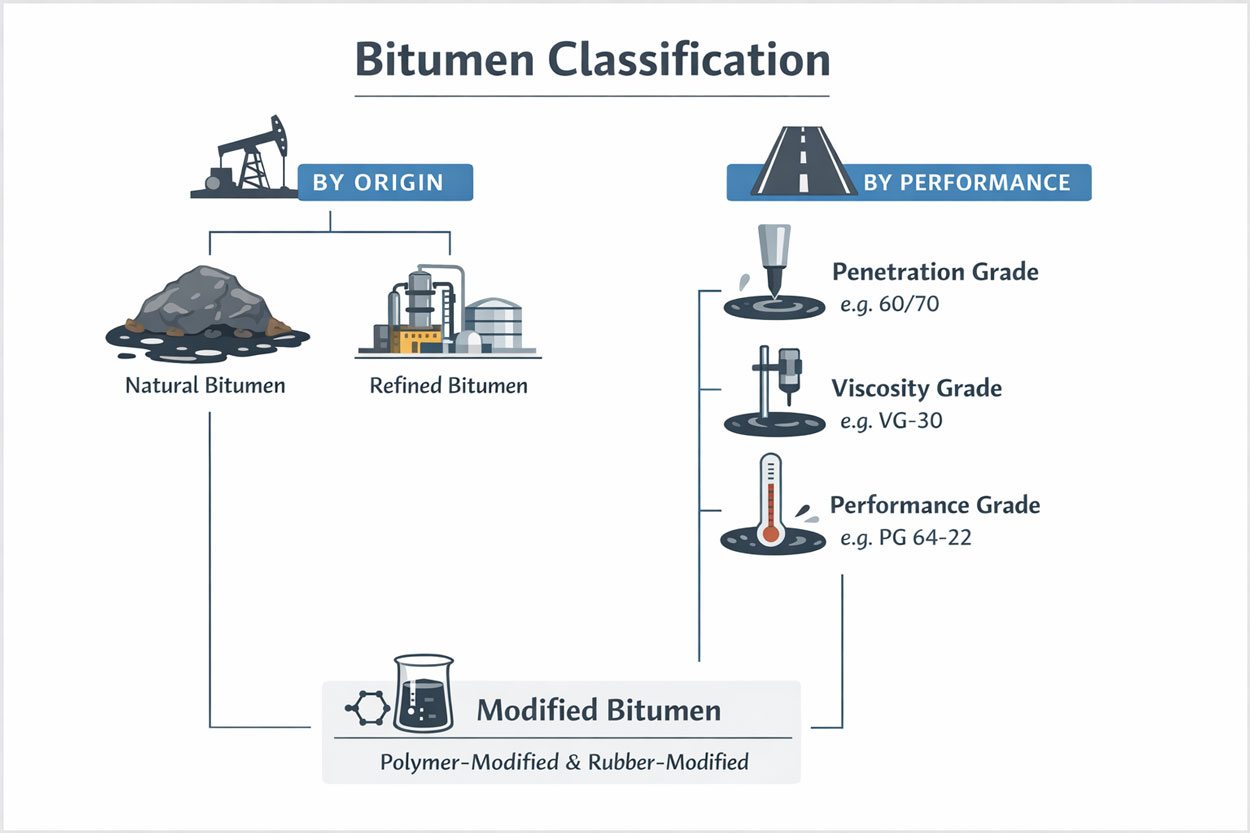

Bitumen is one of the most widely used petroleum-based materials in modern infrastructure, yet it is often misunderstood due to the variety of classifications, grades, and technical terms associated with it. From road construction and waterproofing to industrial insulation and specialized applications, bitumen plays a critical role—but not all bitumen types behave the same way or serve the same purpose.

The existence of different types of Bitumen is not arbitrary. Each type has been developed in response to specific performance requirements, environmental conditions, and operational constraints. Factors such as temperature variation, load stress, application method, and durability expectations all influence how bitumen is produced, processed, and classified.

This article is designed to provide a clear, structured explanation of the topic without turning into a technical catalog or an overly simplified definition. Instead of listing specifications in isolation, the focus is on helping readers understand why different types exist, how they differ in behavior, and when each category is typically used. The goal is to build a practical mental framework that makes technical information easier to interpret and apply.

As part of the educational resources published by Farazoil this guide aligns with real-world industry practices and common use cases across global markets. For readers who are new to the subject or seeking a foundational reference, a general overview of Bitumen is available separately while this article focuses specifically on classification and application logic.

By the end of this guide, you should have a clear understanding of how different bitumen types are categorized, what differentiates them in practice, and how these differences translate into real-world usage.

About this article: This guide is prepared by a technical content team specializing in bitumen, asphalt binders, and industrial petroleum materials. The explanations are based on practical industry usage, standard classification systems, and performance-oriented selection principles.

Penetration Grade Bitumen

Penetration grade bitumen is one of the oldest and most widely used classification systems in the bitumen industry. Its popularity stems from its simplicity: it categorizes bitumen based on hardness, measured under standardized conditions. Despite the emergence of more advanced grading systems, penetration grades remain highly relevant in many regions and applications.

The classification is based on a penetration test in which a standard needle is allowed to penetrate the bitumen sample under controlled temperature, load, and time conditions. The depth of penetration—measured in tenths of a millimeter—indicates the relative hardness of the material. Lower penetration values correspond to harder bitumen, while higher values indicate softer material.

From a practical perspective, penetration grade bitumen has been extensively used in road construction because it offers predictable behavior under moderate climatic conditions. Grades such as 60/70 or 80/100 have become industry benchmarks, especially in regions where temperature variations are not extreme. These grades provide a workable balance between flexibility and resistance to deformation, making them suitable for general-purpose paving.

However, penetration grading has inherent limitations. The test reflects bitumen behavior at a single temperature and does not fully capture how the material performs under varying thermal or loading conditions. In hot climates, for example, two bitumens with the same penetration grade may behave quite differently in terms of rutting resistance. This limitation is one of the key reasons why alternative grading systems were later developed.

Despite these constraints, penetration grade bitumen remains an important reference point. It is easy to specify, widely understood, and still performs reliably when used within appropriate environmental and design boundaries. For many standard road projects, it continues to serve as a practical and cost-effective solution.

Viscosity Grade (VG) Bitumen

Viscosity Grade (VG) bitumen was introduced to address some of the practical limitations associated with penetration grading, particularly in regions exposed to higher service temperatures. Instead of focusing solely on hardness at a single temperature, VG classification evaluates resistance to flow, which is a more direct indicator of how bitumen behaves during mixing, laying, and in-service conditions.

VG bitumen is classified based on its absolute viscosity at 60°C and, in some cases, its kinematic viscosity at 135°C. These temperatures are not arbitrary. The 60°C benchmark represents conditions close to maximum pavement service temperatures in hot climates, while 135°C reflects the temperatures encountered during hot mix asphalt production and handling. Together, these measurements provide a clearer picture of bitumen behavior across critical operational stages.

From a performance standpoint, viscosity grading offers better control over rutting resistance compared to penetration grading. A higher-viscosity bitumen is more resistant to permanent deformation under heavy traffic loads, making VG grades particularly suitable for high-traffic roads and warm environments. This is why VG bitumen has been widely adopted in countries with demanding climatic and loading conditions.

Another advantage of VG classification is its improved consistency. While penetration tests are empirical and can vary in interpretation, viscosity measurements are more fundamental and repeatable. This makes VG grades more reliable when uniform performance is required across large infrastructure projects.

That said, VG grading is still a partial solution. Although it provides a better understanding of high-temperature behavior, it does not fully account for long-term aging or low-temperature cracking performance. These gaps eventually led to the development of more comprehensive, performance-based systems.

In practice, VG bitumen represents an important step forward in classification logic—bridging the gap between simple empirical grading and fully performance-driven evaluation. It remains a preferred choice where temperature control and deformation resistance are critical design considerations.

Viscosity grade classifications are commonly defined and referenced under widely used standards such as ASTM, AASHTO, and equivalent national specifications. These frameworks help ensure consistency in material selection and performance expectations across different projects and regions.

Performance Grade (PG) Bitumen

Performance Grade (PG) bitumen represents a fundamental shift in how bitumen is evaluated and selected. Unlike earlier systems that rely on individual physical properties, PG classification is built around a single guiding principle: how the material performs under real service conditions. This approach was developed to reduce the gap between laboratory testing and actual field behavior.

PG bitumen is classified based on the temperature range within which it can perform satisfactorily. Each grade is defined by two numbers: the first indicates the highest pavement temperature the bitumen can withstand without excessive deformation, and the second represents the lowest temperature at which it can resist cracking. For example, a grade such as PG 76-16 is designed to perform well in environments where pavement temperatures reach up to 76°C and drop as low as -16°C.

What distinguishes PG grading is its reliance on rheological and aging tests that simulate real-world conditions. Tests such as the Dynamic Shear Rheometer (DSR) evaluate resistance to rutting and fatigue, while aging simulations account for how bitumen properties evolve over time. This ensures that the selected material is not only suitable at the time of application but remains effective throughout its service life.

From a design perspective, PG bitumen enables engineers to match material performance precisely to climate and traffic conditions. This makes it especially valuable for highways, heavy-load corridors, and regions with extreme temperature variations. Rather than relying on assumptions or averages, PG grading provides a scientifically grounded framework for decision-making.

However, the sophistication of PG classification also comes with increased complexity and cost. Testing requirements are more extensive, and implementation may not be practical for all projects. As a result, PG bitumen is most commonly used where performance reliability justifies the additional investment.

In summary, PG bitumen is considered the most advanced and performance-oriented grading system available today. It does not replace earlier systems entirely but complements them by offering a higher level of precision where long-term durability and environmental adaptability are critical.

Specialized and Non-Paving Bitumen Types

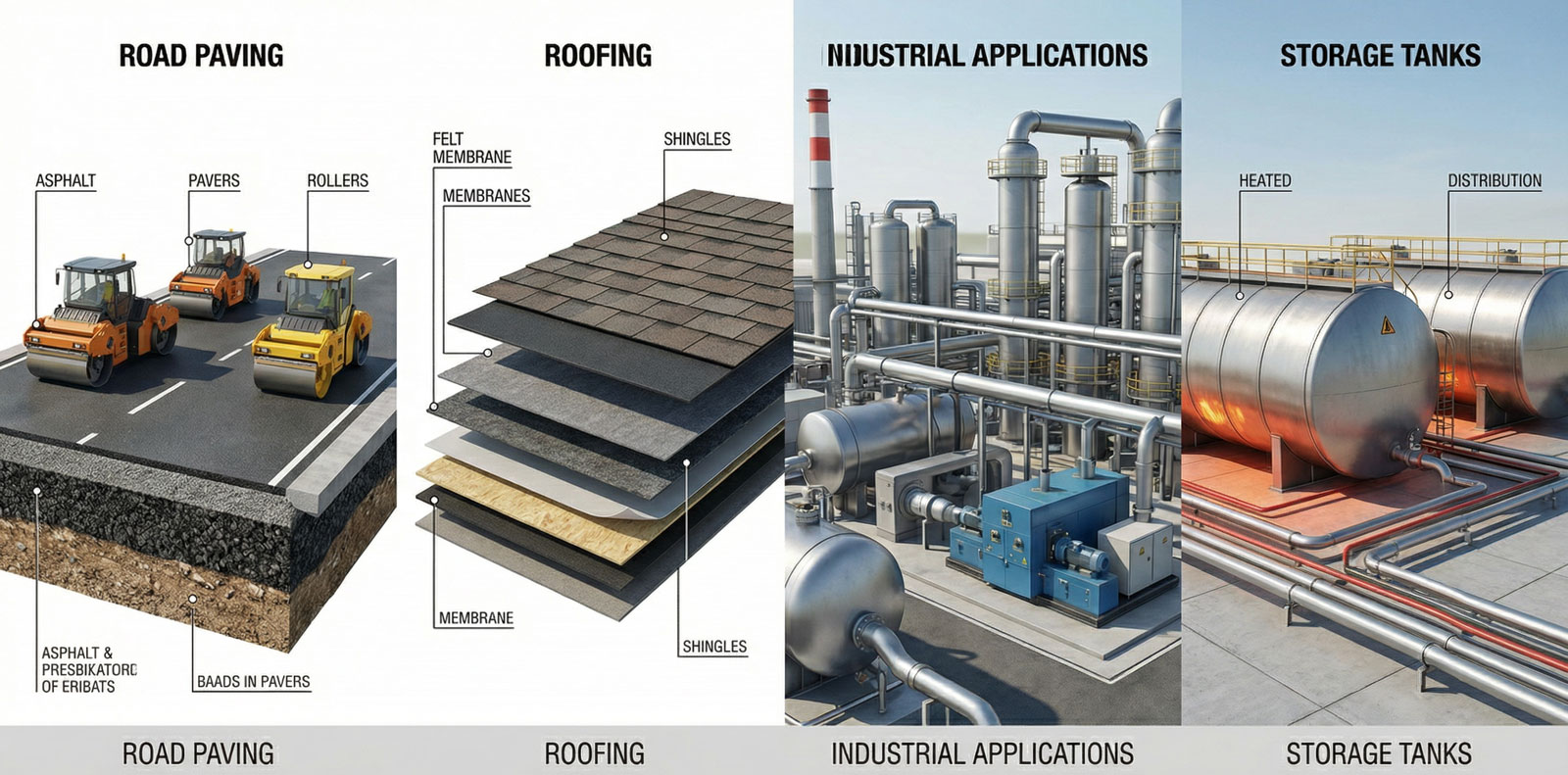

Not all bitumen types are designed for road construction. Some grades are specifically engineered for industrial, waterproofing, insulation, and protective applications where load-bearing traffic performance is not the primary requirement. The following categories focus on bitumen types optimized for stability, durability, and application-specific behavior rather than pavement flexibility.

Oxidized (Blown) Bitumen

Oxidized bitumen, also known as blown bitumen, is produced by passing air through hot petroleum bitumen under controlled conditions. This process triggers oxidation and polymerization reactions within the material, resulting in a significant change in its internal structure and physical behavior.

Compared to penetration or viscosity grade bitumen, oxidized bitumen is harder, less temperature-sensitive, and more resistant to flow. The oxidation process increases the proportion of larger molecular components, which raises the softening point and reduces penetration values. As a result, this type of bitumen maintains its shape and stability even at elevated temperatures.

The primary purpose of oxidizing bitumen is to tailor it for applications where deformation resistance and thermal stability are more important than flexibility. For this reason, oxidized bitumen is rarely used in road paving. Instead, it is widely applied in industrial and construction sectors such as roofing membranes, flooring systems, pipe coating, and waterproofing layers.

Another defining characteristic of oxidized bitumen is its predictable performance in static or semi-static conditions. Since it is less sensitive to temperature fluctuations, it performs reliably in environments where consistent physical behavior is required over time. However, this same rigidity makes it unsuitable for applications involving repeated dynamic loading or significant thermal movement.

In practice, oxidized bitumen serves a very specific role within the broader bitumen landscape. It is not designed to compete with paving grades but to meet the demands of non-road applications that require durability, heat resistance, and dimensional stability.

Cutback Bitumen

Cutback bitumen was developed to solve a practical challenge: how to reduce the viscosity of bitumen for easier handling and application without the need for high temperatures. This is achieved by blending penetration grade bitumen with petroleum solvents such as gasoline, kerosene, or diesel, creating a fluid material that can be applied at or near ambient temperatures.

The defining feature of cutback bitumen is its curing behavior. After application, the solvent gradually evaporates, leaving behind a residual bitumen binder that performs its intended function. Based on the rate of solvent evaporation, cutback bitumen is classified into three main categories: Rapid Curing (RC), Medium Curing (MC), and Slow Curing (SC). Each category is designed to match specific construction conditions and application methods.

From a practical standpoint, cutback bitumen has been widely used in cold mix asphalt, surface treatments, and maintenance works where heating facilities are limited or impractical. Its ease of application made it particularly attractive for remote projects and temporary works.

However, the same solvents that make cutback bitumen workable also introduce significant drawbacks. The evaporation of petroleum solvents contributes to environmental pollution and poses safety risks during handling and transportation. As environmental regulations have tightened and sustainability concerns have grown, the use of cutback bitumen has declined in many regions.

Today, cutback bitumen is increasingly viewed as a transitional solution rather than a long-term one. While it still has niche applications, especially in specific maintenance scenarios, it has largely been replaced by more environmentally responsible alternatives.

In many modern projects, cutback bitumen is avoided entirely due to environmental regulations, making it unsuitable for long-term or sustainability-focused applications.

Emulsion Bitumen

Emulsion bitumen was developed as a more environmentally responsible alternative to cutback bitumen, addressing many of the safety and pollution concerns associated with petroleum solvents. Instead of using hydrocarbons to reduce viscosity, this type of bitumen is produced by dispersing fine bitumen droplets in water with the help of an emulsifying agent.

In an emulsion, bitumen particles are suspended in water in a stable form, allowing the material to be applied at low temperatures without the need for heating. Once applied, the emulsion “breaks” as water evaporates or separates, and the bitumen particles coalesce to form a continuous binding film. This mechanism makes emulsion bitumen both practical and energy-efficient.

Emulsion bitumen is classified primarily based on two factors: the electrical charge of the bitumen particles and the setting time. Depending on the emulsifier used, emulsions can be cationic (positively charged) or anionic (negatively charged). Cationic emulsions are more commonly used in modern road construction because they adhere better to aggregates with negative surface charges, such as siliceous materials.

Setting time further categorizes emulsions into slow-setting, medium-setting, and rapid-setting types. This allows engineers to select an emulsion that matches site conditions, aggregate properties, and construction speed requirements. Unlike cutback bitumen, emulsion bitumen does not rely on solvent evaporation, making it safer to handle and significantly less harmful to the environment.

In practice, emulsion bitumen is widely used for surface treatments, tack coats, slurry seals, and cold mix applications. Its ability to perform without extensive heating infrastructure makes it especially valuable for maintenance works, urban environments, and projects with sustainability constraints.

Polymer Modified Bitumen (PMB)

Polymer Modified Bitumen (PMB) is engineered to overcome the performance limitations of conventional bitumen under demanding service conditions. By incorporating polymers into the base bitumen, PMB exhibits enhanced elastic and mechanical properties that significantly improve durability and resistance to distress.

The role of polymers is to modify the viscoelastic behavior of bitumen. Elastomeric polymers, such as styrene–butadiene–styrene (SBS), increase elasticity and recovery after deformation, while plastomeric polymers improve stiffness and resistance to permanent deformation. These modifications allow PMB to perform more effectively under heavy traffic loads, wide temperature fluctuations, and repeated stress cycles.

From a functional standpoint, PMB is particularly effective in reducing rutting at high temperatures and minimizing cracking at low temperatures. This dual benefit makes it a preferred choice for highways, airports, and high-performance pavements where long service life is critical. Although PMB typically costs more than conventional bitumen, the reduction in maintenance and repair frequency often justifies the initial investment.

Another important advantage of PMB is its adaptability. By adjusting polymer type and concentration, bitumen properties can be fine-tuned to meet specific project requirements. This flexibility enables engineers to design binders that align closely with local climate conditions and traffic demands.

In practice, PMB is not intended for universal use. Its application is most effective where performance demands exceed the capabilities of standard grades. When selected strategically, polymer modification represents a practical balance between advanced performance and long-term economic efficiency.

When PMB may not be the right choice: Polymer Modified Bitumen is not always necessary or economical. For low-traffic roads, mild climates, or short design life projects, the added cost and complexity of polymer modification may not deliver proportional performance benefits. In such cases, conventional penetration or viscosity grade bitumen can be a more practical solution.

Natural Bitumen (Gilsonite)

Natural bitumen, commonly referred to as Gilsonite, differs fundamentally from refinery-produced bitumen in both origin and function. It is a naturally occurring solid hydrocarbon formed through long-term geological processes that remove lighter fractions and concentrate heavier molecular components. This results in a material with exceptionally high asphaltene content and distinctive physical properties.

Unlike conventional bitumen, Gilsonite is not typically used as a standalone binder. Its primary value lies in its role as a performance-enhancing additive. When blended with petroleum-based bitumen, it increases stiffness, improves resistance to deformation, and enhances moisture resistance. These characteristics make it particularly useful in applications where conventional binders require reinforcement.

In asphalt production, Gilsonite is often added to improve high-temperature performance and reduce rutting, especially in heavily trafficked pavements. It also contributes to better bonding between binder and aggregate, which enhances overall mixture durability. Beyond road construction, natural bitumen is widely used in industrial applications such as drilling fluids, coatings, paints, inks, and waterproofing compounds.

Another important advantage of Gilsonite is its purity and compatibility. It dissolves readily in aromatic hydrocarbons and blends well with other petroleum products, allowing for precise control over formulation outcomes. Its solid form also simplifies storage and transportation compared to liquid binders.

In practical terms, natural bitumen occupies a specialized but strategic position within the bitumen family. Rather than competing with conventional grades, it complements them by enabling targeted performance improvements in both infrastructure and industrial uses.

Conclusion

Bitumen is not a single, uniform material but a family of binders engineered to meet very different performance demands. The wide range of classifications—penetration, viscosity, performance-based systems, modified binders, and natural additives—exists because infrastructure, climate, and application methods vary significantly from one project to another.

Rather than asking which bitumen type is “best,” a more accurate question is which type is most appropriate for a specific purpose. Penetration and viscosity grades offer simplicity and practicality for conventional applications, while performance grade systems provide higher precision for demanding environments. Oxidized bitumen serves non-road industries where thermal stability is critical, cutback and emulsion bitumen address application and temperature constraints, polymer modification enhances long-term durability, and natural bitumen functions as a targeted performance booster.

Understanding these distinctions allows engineers, contractors, and decision-makers to move beyond product names and focus on behavior, suitability, and expected service life. When bitumen selection is aligned with real operating conditions rather than habit or convenience, the result is more reliable performance, lower maintenance costs, and improved project outcomes.

As with most engineering materials, informed selection—not complexity—defines success. A clear grasp of how and why different bitumen types exist is the foundation for making confident, technically sound decisions.

If bitumen selection is being made for a specific climate, traffic level, or application method, understanding how these categories translate into real-world performance becomes critical. Matching binder type to operating conditions—not habit or availability—is what ultimately defines long-term success.